Order-to-cash is an important business process that manages full lifecycle of a customer order starting from customer order receipt and ends when payment is received.

By streamlining Order-to-cash process businesses can reduce cost, improve

customer relationship and increase overall efficiency.

Order-to-cash is also known as OTC and O2C.

Let us understand Order-to-cash process.

Order Management

>> Credit Management >> Order Fulfilment >> Shipping >>

Invoicing >> Account Receivables (AR) >> Data Management & Reporting

1. Order Management: The first step of O2C process is Order

management. The process starts once customer places an order, customer may

place the order through company portal/ ecommerce website / on call / email.

Once order received and confirmed, it is sales department's responsibility to

validate the order by checking few things such as product, quantity, price,

availability, customer & delivery details etc., after checking these

information sales department does the order login in their system (enterprise

resource planning - ERP or order management system - OMS) and send a confirmation

(acknowledgement) of order with delivery date and other relevant

information to the customer.

2. Credit Management: Once order login completed, the data of new

orders are transferred to the Credit department automatically by ERP/ OMS. If

credit term is applicable, credit department checks for credit worthiness of

the buyer.

If it is a first time customer, the department analyzes customer's financial

history, business credit score, financial stability, payment behavior etc.

after analyzing all these details, credit department avail eligible credit

limits to the customers.

If it is returning customer with existing credit limit, the credit department

checks the value (amount) of the new order, if it is within the existing credit

limit it's fine otherwise the order goes to credit block.

If it is returning customer without existing credit limit, the credit

department treat it as a new customer and analyze it's credit worthiness.

All orders except prepaid (100% advance payment) orders should be on credit

block by default, and the one should be unblocked as per the allocated credit

limit.

3. Order Fulfillment: Order fulfilment is the process of keeping

the finished goods at distribution center temporarily, picking, packing,

shipping & delivering of goods at correct customer address.

Picking: In a warehouse different products are stored at different locations.

Once an order is logged in to the system the information gets transferred to

warehouse system (WMS) too, now the responsibility of warehouse team is to

retrieve the ordered product from stored location without any error, this

process is called & picking.

Packing: The products which are picked for shipping have to be packed correctly

as per the guidelines and industry standard so that the product doesn't get

damaged during transit.

Labeling: Labeling is also an important part to fulfilment, correct labels

needs to be attached with the product, invoices & other custom documents

are also attached along with the product for further requirements.

4. Shipping: Shipping is an important part of O2C process. Once

products are manufactured and sent to the warehouses or distribution centers

where picking & packing is done, the next step is to arrange transport

& deliver (to customer) the order at right place on right time. In this

step transport department does the analysis and finalize the mode of transport,

whether the product will be shipped through roadways, railways, waterways or

airways. Then the department needs to choose a carrier based on their analysis

and dispatch the product.

Track & Trace: In between dispatch of the goods from the warehouse &

arrival of at customer's premises, the order needs to be tracked and updated in

the system so that if customer wants to check the status of his order, he can go

to the website and click on tracking link to get the update of his order.

5. Invoicing: Proper invoicing is crucial for financial management.

While generating invoice the team needs to check few things properly such as

customer details, price, taxes, discount, shipping charges, payment terms. Once

invoice is created it must be sent to the customer either automatically by

system or by manually.

6. Accounts receivable (AR): Account receivable (AR) is a crucial

process, once invoice is sent to the customer, it's AR department's

responsibility to collect the payment on or before due date. AR keeps track of

credit line, payment due dates, customer wise outstanding, collections etc. and

as per the ledger statements they keep sending payment reminders to the

customers periodically until payment received.

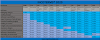

7. Data Management & Reporting: All data starting from order

creation and ending with payment receipt are captured using ERP system or

manually using spreadsheets, the data flows from one step to another which is

accessible to all departments (based on the provided access).

Example:

Let us understand this with an example, suppose a customer placed an order and

the order management department receive order details, OM team does the order

login and other formalities and update all data in the system, the data flows

by the system to the next level where credit management team analyzes the data

and allocates credit limit to the customer, then the credit information along

with other details flows to the fulfilment department where the team takes care

of all the activities, after that the outbound/ logistics team ship the goods

and update all tracking information in the system, customer service team gets

all the data and creates invoice and sends to the customer, accounts receivable

team sends payment reminders and does follow-up based on the invoice data, once

payment is received all details (order no, invoice no etc.) are updated in the

system and finally all these data are used to create various reports.

0 Comments